Innovations in Industrial Embroidery Machine Technology Every CMT Business Should Know

27 May 2022

Innovations in Industrial Embroidery Machine Technology Every CMT Business Should Know

The industrial embroidery machine is a decades-old innovation that, like most brilliant innovations, started out as a seed — hand embroidery machines. In the mid-nineteenth century, close to Mulhouse, France, Joshua Heilmann revolutionized the textile industry by creating a device that partially automated the hand embroidery process.

The giant hand embroidery machine could do the work of four human embroiders. It had three major components: a wall-mounted frame to hold fabric, a needle apparatus, and a hand crank. Unlike modern embroidery machines, Heilmann’s had a stationary needled, and operators had to manoeuvre the material to where the needle was using a hand crank. The embroidery needle was quite different, too. It had a point at each end and an eye in the middle, which allowed stitching in any direction.

Modern Advances in Commercial Embroidery MachinesEmbroidery machine technology has come a long way since the 1800s. Modern innovators are constantly pushing the envelope to make computerized embroidery machines more efficient, user-friendly, and versatile. Some of the latest developments include higher speeds, more needles per head, an abundance of attachments per head, and precision-cutting with laser technology.

Let’s delve into the six biggest advances in industrial embroidery technology and how your CMT business benefits from each.

1. Multi-needle Embroidery MachinesOne of the earliest innovations to the commercial embroidery is the multi-needle embroidery machine. Where traditional embroidery has limited embroiders to using one needle and one thread at a time, modern embroidery machines easily accommodate 12 needles per head. Embroiders assign a different thread colour to each needle, which saves time on changing colour. Some multi-needle embroidery machines also let you pre-set certain needles ahead of time based on a digital design pattern or your daily workflow.

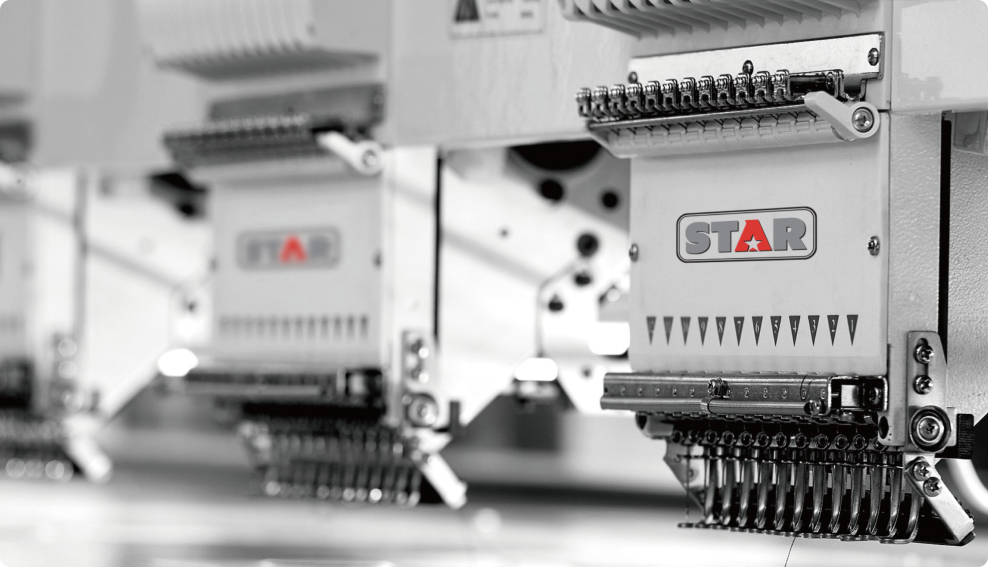

Our Star embroidery machines, for instance, come standard with 12 needles for easy and automatic colour changes. With the Star ST 1201 single head embroidery machine, you could seamlessly produce samples for monochrome or multi-colour designs without manually changing threads.

2. Multi-head Embroidery MachinesAnother classic development in embroidery technology was the invention of multi-head machines. Dating back to the early 1911, the multi-head embroidery machine skyrocketed commercial embroidery. With the single-head machines, embroidery factories could only produce one garment design per machine.

Now, industrial-sized embroidery machines can work on multiple orders simultaneously boosting productivity. The Star multi-head embroidery machines range from two heads to eight per machine.

Then, there’s the independent stop/start technology, which lets embroiders control each head separately. So, if the ST 1204 detects an embroidery error on one of the heads, all heads will stop, and you will have to manually switch off the error head before continuing with work.

3. Embroidery Hardware InnovationsThen, there are the hardware design innovations. Embroidery technology has come a long way from the days of noisy machines in need of regular oil changes. They built newer embroidery machines with sealed bearing and belts that don’t require lubrication, reducing the need for costly maintenance and oil.

While wear and tear still occur, maintenance on newer models is budget friendly and far less time-consuming. Most embroidery machine manufacturers include spare parts, extra needles, and guarantees with each machine, so you can rest at ease knowing your embroidery machines will work efficiently for years to come. The noise reduction frees shop owners to start an embroidery business at home.

4. Software for Commercial Embroidery MachinesNow, let’s shift gears from hardware innovations to the latest digital embroidery technology. Embroidery machines are not quite in the meta verse yet, however, digitization is becoming a core part of new embroidery machines. To start, contemporary embroidery machines come standard with touch display control panels.

Furthermore, you can store designs on the machine control panel’s built-in memory, so you have access to often requested designs. Moreover, the software developments can help you plan workflows and processes well in advanced.

5. Time-saving Attachments for Embroidery MachinesAttachments are by far the greatest revolution in embroidery technology. Over the decades companies have developed embroidery machine attachments and accessories to boost efficiency and increase profitability.

The following are among the best time-saving embroidery machine attachments:

- Garment and size attachments. Transform a standard embroidery machine into a

specialist with attachments for different garments, frames, and sizes. Cap attachments

and border frames allow you to switch between designs without changing the

machine. Since designs can be preloaded onto an embroidery machine’s control panel,

you can switch from cap to flat by changing attachments. - Thread colouring attachments. Thread colouring products, such as Coloreel, tint the

thread colour while the machine runs. Instead of stocking thread in different colours,

these attachments make it possible for shops to stockpile one colour and use the

Instant Thread Colour Unit to dye the thread on demand. - Bead and sequins attachments. Last, give clients the hand-embroidered feel by

adding sequins and beading attachments to an embroidery machine. The ground-

breaking technology gives shop owners the freedom to deliver intricate orders that

incorporate layers of sequins and beading. The possibilities are endless.

6. Improved CMT Business Management AutomationFinally, one of the biggest innovations is automation software designed with CMT businesses in mind. Software companies, such as OnSite, have created embroidery business management software to aid in the day-to-day management of your business.

A key feature of the OnSite software is the built-in price calculator that automatically adjusts an order’s price based on factors like design complexity, colours, materials, and size. Once it is set up, invoicing and processing orders becomes an effortless process. It also allows shop owners to create a tiered pricing system and automate discounts for bulk orders.

Leap Into the Future of Embroidery MachinesWith each innovation, CMT manufacturing is changing for the better. Navigating those changes with a trusted partner makes the journey easier. Our expert team at Square Deal supports South African CMT businesses through every evolution of sewing and embroidery machines, ensuring you build a thriving business for your customers and employees.

Ready to leap into the future of CMT manufacturing? Schedule a free consult with a Square Deal expert today.